Step by Step Instructions

Instructions, temperature and time guides, tips, and tricks to help you apply your U-Press transfer sheets.

Easy DTF Application Process

-

Place your garment

Place your garment on the heat press and ensure that there are no wrinkles

-

Press to preheat

With your press set to the correct temperature and pressure, press the garment for 5 seconds.

-

Place transfer sheet

Place the transfer sheet on the garment, ensuring that it is properly centered and oriented.

-

Press the transfer

Pressure should be Medium/Heavy.

Cotton: 305-325°F for 10-20 seconds

Polyester: 275-285°F for 5-10 seconds

-

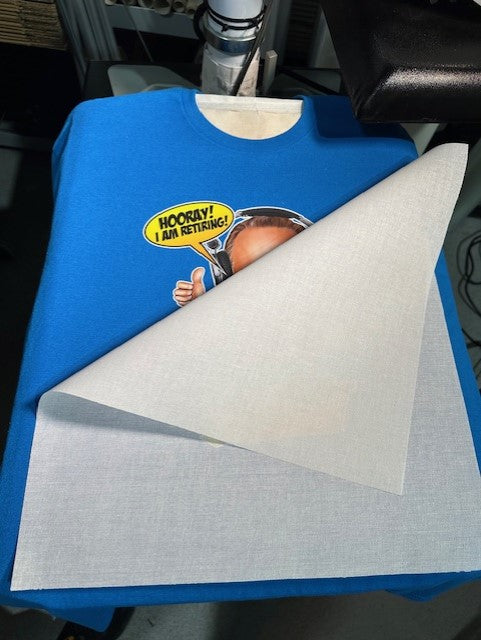

Peel the transfer sheet

Our transfers can be peeled HOT or COLD. Hot peel must be done fast and with not hesitation, like ripping off a bandage. Cold peel by letting transfer cool and gently peeling. If there is any pull up, let it cool and try a different angle.

-

Cover with parchment

Place parchment paper or top sheet onto the garment, fully covering the design.

-

Press the design

Press the design for five seconds or more at the correct temperature and pressure.

-

Voila!

Your design is now on the garment. That sure was easy!

How to get the most out of your U-Press DTF transfer sheets

- If the transfer fails to adhere to the garment, feel free to re-press it. Additional re-presses will not harm the transfer.

- If applying to a 50/50 blend, use the instructions for Polyester instead of Cotton, as the temperature is lower and will prevent scorching.

- For better washability, increase finishing time, temperature, and pressure.

- Avoid placing transfer near seams, collars, or pockets due to the uneven pressure created in these areas. A heat pillow can be placed under the substrate to mitigate this.

- Always preheat polyester and nylon for 10 seconds before pressing to avoid shrinkage and promote adhesion.

- Always place the transfer media in the center of the heat press.

- Select a less-stretchy fabric (not Lycra or Spandex) to prevent design from cracking when stretching fabric.

Sublimation Application

-

Step 1

Preheat your heat press (standard settings below)

-

Step 2

Prepare your substrate: make sure the fabric or item is lint-free and clean.

-

Step 3

Align your transfer face down on the item. Tape it in place if needed to prevent shifting.

-

Step 4

Cover with blowout paper to avoid ink transfer onto the press.

General Heat Press Settings

Item | Temp | Time | Pressure

Polyester Shirts | 385–400°F | 45–60 sec | Medium

Sublimation Mugs | 375–400°F | 180 sec | Medium

Metal or Hardboard Blanks | 400°F | 60 sec | Medium